Testing and Validation

Validating

EV Components

The powertrain market is shifting away from fossil fuels to all electrical-powered engines. The trend is significantly speeding up over the past years and large automotive manufacturers are committing to 100% electric vehicle (EV) fleets within the next 10 years – Opel being the most recent one, announcing an aggressive target by 2028. (Automotive News Europe, 2021) The implication of the development is heavy innovation in the market of transportation and its many components. To make the shift work suppliers and manufacturers are investing in R&D to increase the efficiency of battery-powered vehicles, by finding lighter materials, and improving existing systems, such as airconditioning and heating.

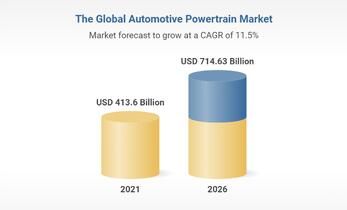

Recent research indicates that the Global Automotive Powertrain Market is going to grow by 11.5% per annum. (Research and Markets, 2021) This is quite a significant growth of the market as a whole. However, researchers indicate that EVs will be the significant driver of this development. Estimating up to 30% (CAGR) to 2027. “The global electric vehicle market was valued at $162.34 billion in 2019 and is projected to reach $802.81 billion by 2027, registering a CAGR of 22.6%.

Asia-Pacific was the highest revenue contributor, accounting for $84.84 billion in 2019, and is estimated to reach $357.81 billion by 2027, with a CAGR of 20.1%. North America is estimated to reach $194.20 billion by 2027, at a significant CAGR of 27.5%. Asia-Pacific and Europe collectively accounted for around 74.8% share in 2019, with the former constituting around 52.3% share. North America and Europe are expected to witness considerable CAGRs of 27.5% and 25.3%, respectively, during the forecast period. The cumulative share of these two segments was 40.1% in 2019, and is anticipated to reach 51.0% by 2027.” (Allied Market Research, 2020)

The Poppe + Potthoff Group

The Poppe + Potthoff Group bundles its activities in the automotive business, in the Industrial Products Division, and a new platform dedicated to innovation. The Group sees market development as a key to growth and “with the new organizational structure, we are strengthening the market orientation and flexibility of our business units and at the same time intensifying cooperation as a Group and with our customers – especially in innovations,” said Dr. Christian Potthoff-Sewing, the main shareholder of Poppe + Potthoff.

Test Stands for Electric Vehicle Components

Battery-powered vehicles face various challenges and are exposed to ever-changing climate conditions. At Poppe + Potthoff Maschinenbau GmbH we offer solutions to support innovation in the automotive industry. Over the years customers approached our team with requests to simulate battery operation while testing the durability of the design life of various media-carrying components.

In order to test quality and validate the quality of media-leading automotive parts, drive units (electric motors), housing, valves, cooling and heating systems, hose lines, pipes, pressure vessels, and other components are pressurized in a controlled test environment. Whether for non-destructive dynamic pressure pulsation tests, static pressure-holding tests, flow measurements, or destructive burst pressure tests, Poppe + Potthoff Maschinenbau offers a solution tailored to our customer’s requirements.

Pressure Pulsation Test Bench for Air Conditioning Components

The test medium used is a water-glycol mixture or pure glycol (for example Glysantin® G40, G44, G48). The refrigeration cycle is tested in the temperature range from -40 to +20 degrees Celsius, and in the heating circuit from +20 to +140 degrees Celsius. The development of alcohol-containing vapours (danger of explosion) is avoided by means of specially-developed closed-circuit test equipment with the help of pressure. Optionally, an additional air-conditioning chamber can also be used to generate environmental simulations.

The volume flow of the test medium can vary from 3 to 30 l/min at a pressure of 0.2 to 10 bar (max 12 bar). The load changes are freely programmable with a sinusoidal or trapezoidal rise in a test frequency of 0.2 to 1 Hz. The test system can be used to test complete systems as well as individual assemblies made of various plastics, metals, and sealants. With the aid of realistic simulation, the weak points in the material composite are precisely determined – for example in the area of a weld seam – and can be optimized early in the development process.

Pressure Test Rig Performance and Highlights

Medium: water-glycol mixture/pure glycol

Medium temperature control: Refrigeration circuit: + 20 ° C to -40 ° C

Cooling capacity up to -30 ° C 5 kW

Cooling capacity up to -40 ° C 2 kW

Medium temperature heating circuit: + 20 ° C to + 140 ° C

Heating power: 12 kW

Flow rate control: 3 to 30 l/min

Ambient temperatures: -40 ° C to + 140 ° C

Dynamic pressure changes: 0.2 to 10 bar

Frequency: 0.2 Hz

Ramp shape: trapezoid & sine

Static pressure drop test: up to 12 bar

With PPM Fine Pressure Control, any pressure curve up to 12 bar can be programmed